Induction Pipe Heating

Skyrocketing global demand for petroleum & gas has driven aggressive efforts in exploration, transportation and environmental safety, resulting in greater demand for tubular products.

A newly developed and patented technology improves the induction heating process used to produce consistent properties to these products. For example: Correct and precise heat treatment of tube ends in well bore casings is essential to prevent leakage catastrophes into ground water aquifers and deep sea drilling environments.

IROSS™ Pipe-End Heating Units are designed specifically for heating a variety of tubular products. These systems utilize patented Fluxmanager® induction heat treatment technology that yields superior temperature uniformity compared to conventional medium frequency designs.

Preheat for welding & swaging • Hardening • Annealing

- Normalizing • Removal and cure of coatings

- Friction weld and swage stress relieving

Fluxmanager® Induction Heat Treatment Features / Benefits:

- Deep and uniform temperature distribution, ID/OD, laterally, and longitudinally along extended lengths of pipe ends

- Achieves uniformity requirement ΔT = +/- 25oC, even when tubes are non-central

- Meets or exceeds API tube & pipe specifications

- Flexible: 4 coil diameters cover all OCTG pipe sizes

- Modular: Robust and unitized system

- Infrared and thermal image monitoring options

- Data logging capability for traceability

- Shaped flux concentrator for increased efficiency

- Deionized water NOT required

- Versatile: 50 or 60Hz / 350 – 600VAC input

- Low Cost & easy to maintain

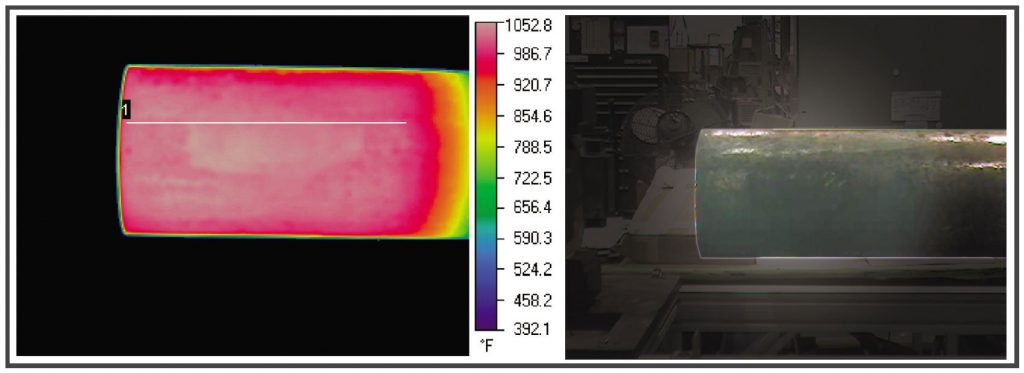

Thermal image, shows advanced temperature control for AISI 8630 Modified tube.

- 194 mm dia. – 19 mm wall

- Heat length 381 mm

- 93 sec. 6ºC range observed.

Sample only:

Each application is validated separately due to different thickness, length and temperature requirements.